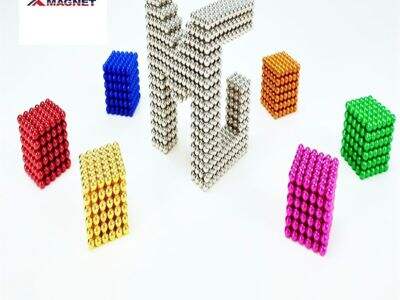

آهنرباهای صنعتی درجهدار، مانند آنهایی که توسط شرکت XINYUAN MAGNET ساخته شدهاند، آهنرباهایی بسیار قوی هستند که ماشینها و ابزارهای موجود در کارخانهها و دیگر مکانهایی که مردم در آنجا اشیاء را میسازند میتوانند از آنها استفاده کنند. این آهنرباها باید سفت و سخت و مقاوم باشند تا حتی با استفاده مکرر بتوانند انرژی خود را حفظ کنند. هنگام تصمیمگیری در مورد آهنرباهای صنعتی چندین عامل کلیدی وجود دارد که باید در نظر گرفته شوند تا اطمینان حاصل شود که آنها برای کار مناسب هستند.

اولین موضوع این است که این آهنرباها چقدر واقعاً قوی و مقاوم هستند.

آنها باید به اندازه کافی قوی باشند تا اشیاء را محکم نگه دارند. و اگر آهنرباها به اندازه کافی قوی نباشند، ممکن است به خوبی کار نکنند و اشیاء ممکن است بیفتند یا بشکنند. آهنرباها همچنین باید دوامدار و سختپوست باشند. و این مهم است زیرا اگر آنها بشکنند، دیگر کار نخواهند کرد و ما مجبور خواهیم شد آنها را با آهنرباهای جدید تعویض کنیم.

عوامل دیگری که باید در نظر گرفت نحوه پاسخگویی آهنرباها به گرما و رطوبت است.

برخی از مکانهایی که از این آهنرباها در آن استفاده میکنیم ممکن است بهخصوصاً گرم یا مرطوب باشند و آهنرباهای معمولی در آنجا به خوبی کار نکنند. مهم است که مطمئن شویم آهنرباهایی که انتخاب میکنیم در این شرایط کاری عملکرد مناسبی داشته باشند. neomagnets مقاومت در برابر سرما یا گرما به این معنی است که آنها میتوانند در دماهای گرم یا سرد بدون شکست کار کنند. مقاومت در برابر زنگزدگی به این معنی است که در مکانهای مرطوب یا گردآلود دچار زنگزدگی یا فرسودگی نمیشوند.

همچنین موارد دیگری نیز در انتخاب آهنرباهای صنعتی مناسب وجود دارند:

اندازه و شکل عوامل مهمی در تعیین اندازه و شکل مناسب آهنربای صنعتی هستند. ماشینها و ابزارهای مختلفی نیاز به آهنرباهایی با اندازه و شکلهای متفاوت دارند تا به خوبی کار کنند. اگر آهنرباهایی که انتخاب میکنید خیلی بزرگ یا خیلی کوچک باشند، ممکن است در جایی که قرار است استفاده شوند جا نگیرند. مغناطیس های نئودیمیوم اگر شکل آنها مناسب نباشد، به خوبی نیز نمیچسبند. بنابراین باید اندازه و شکل مناسبی را برای کار انتخاب کنیم.

مواد مختلفی که برای آهنرباهای صنعتی استفاده میشوند را نیز باید در نظر گرفت.

بسیاری از این مواد در واقع یکسان هستند: آهن، کبالت، نیکل. هر کدام از آنها مزایا و معایب خاص خود را دارند، بنابراین باید بهترین گزینه را برای کار مورد نظر انتخاب کنیم. برخی از آنها مقاومت بیشتری در برابر دمای بالا یا خوردگی دارند؛ دیگران قویتر هستند. اگر بدانیم تمام این مواد چگونه کار میکنند، میتوانیم بهترین گزینهها را به عنوان آهنربا برای هر کاری که میخواهیم انجام دهیم، انتخاب کنیم.

در نهایت، بیایید کاربردهای خاص آهنرباها را در شغل مورد نظر در نظر بگیریم. برخی از انواع کارها نیازمند مغناطیس انجام کارهای خاصی هستند — برای مثال، بلند کردن اشیاء سنگین یا جداسازی تکههای فلزی. ما فقط باید آهنرباهای مناسب برای این عملکردها را انتخاب کنیم. این میتواند شامل انتخاب آهنرباهایی با پوششها یا شکلهای خاص باشد که اجازه میدهند تا کار بهطور موثرتری انجام شود. با در نظر گرفتن این عوامل، میتوانیم مطمئن شویم که برای هر کاربرد خاص، آهنرباهای مناسب را بهدرستی انتخاب کردهایم.

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

MK

MK

KA

KA

UR

UR

BN

BN