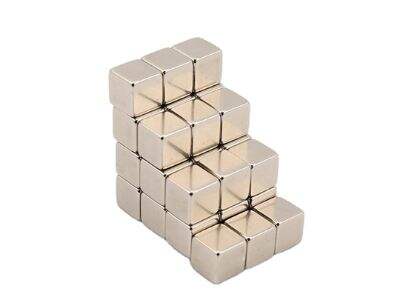

Neodīms ir ļoti spēcīgs magnētu veids, ko bieži var atrast visā, no rotaļlietām, skaļruņos, līdz medicīnas ierīcēm. Šie magnēti ir izgatavoti no īpašas vielas, ko sauc par neodīmu, un ir ļoti spēcīgi.

Toleranšu uzkrāšanās neodīma magnētu montāžām

Kad neodīma magnēti tiek piemēroti produktiem, lielākoties tos integrē ar citām detaļām, lai sasniegtu funkcionalitāti. Dažkārt, kad dažādas detaļas tiek savienotas, var būt nelielas izmēra vai kontūru atšķirības. To sauc par toleranšu uzkrāšanos.

Neodīma magnētu iegulto montāžu kontrole

Ir kritiski svarīgi kontrolēt šīs atšķirības, jo tās var uzkrāties un ietekmēt, cik labi magnēti un citas detaļas turas kopā. Patiesībā, ja detaļas nesaskan precīzi, tas var izraisīt problēmas ar produkta darbību.

Tolerances nozīme neodīma magnētu matricā

Toleranse ir vissvarīgākais, runājot par neodīma magnētu komplektiem, un pat vismazākā izmēra novirze var ievērojami ietekmēt divu detaļu savstarpējo darbību. Ja toleranse netiek pareizi kontrolēta, magnēti var nesakristies, kas negatīvi ietekmēs visa produkta darbību.

Daži ieteikumi toleranšu uzkrāšanās ierobežošanai neodīma magnētu komplektos

Toleranšu uzkrāšanās: viens no faktoriem, ko var ierobežot neodīma magnētu komplektos, ir toleranšu uzkrāšanās; tā notiek tad, kad vairākām sistēmai svarīgām detaļām ir jābūt precīzi apstrādātām, lai tās iekļautos šaurās un noteiktās toleransēs. Citām vārdiem sakot, katrai detaļai jābūt tieši tādam pašam izmēram kā visām pārējām. Vēl viena metode ir atrast īpašus rīkus vai metodes, lai uzlabotu detaļu savstarpējo izvietojumu.

Neodīma magnētu komplekti: toleranšu pārvaldības nozīme precīzai izvietošanai

Ļoti precīza izvietošana neodīma magnētu komplektos ir sasniedzama, ja pieļaujamās novirzes tiek labi kontrolētas. Tādējādi viss perfekti iederas kopā, kad viss tiek savienots, kas ir kritiski svarīgi, lai produkts veiktu paredzētās funkcijas! XINYUAN MAGNET vienmēr koncentrējas uz pieļaujamo noviržu pārvaldīšanu, lai nodrošinātu visu neodīmu magnētis komplektus tiek ražoti saskaņā ar augstiem kvalitātes kontroles standartiem.

Kopsavilkumā, pieļaujamo noviržu kumulācija ir kritiski svarīgs faktors, ņemot vērā neodīma komplektus. Nu, varianču kontrole un pieļaujamo noviržu samazināšana ir daži no veidiem, kas ļauj veiksmīgi izlīdzināt detaļas un garantēt, ka jūsu produkts darbojas tā, kā tam jābūt. XINYUAN MAGNET ir atbildīgs par kvalitātes kontroli un pieļaujamo noviržu regulēšanu.

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

SQ

SQ

ET

ET

TH

TH

TR

TR

FA

FA

GA

GA

BE

BE

MK

MK

KA

KA

UR

UR

BN

BN