Ferrite ring magnets might not be eye catching and difficult to ignore, but they remain relevant in the engineering world. These magnets, made of iron oxide and other elements have distinct properties that enable them to be used for a variety of applications in different industries. From gaining insight into the complexities of ferrite ring magnets, to understanding their potential for increased efficiency and reduced noise pollution - as well as supporting sustainability in general turbine designs- explore below just how these can be a versatile component for almost any application.

Many electronic devices are in essence built around a search for optimization were there is the intention of doing more with less energy. For this, ferrite ring magnets have an important role to play. In transformers and inductors, they function as cores around which the magnetic field due to electric current passes. By amplifying, this process dramatically reducing energy loss in power transmission increasing increase efficiency and also makes more battery life for smartphones or laptops to tulang help support electric vehicle applications. In addition, the low electrical conductivity of ferrite limits eddy current losses which helps to make these components operational and free-running cool.

In the modern age of technology, it is necessary we focus on managing Electromagnetic interference ( EMI) in order to maintain device performance and signal integrity. Among these invisible valiant soldiers are ferrite ring magnets. Fitted around cables and wires, these magnets act as EMI suppressors or chokes - absorbing high-frequency signals that may interfere with the primary data transmission in a circuit. Whether used in sensitive medical devices or high-speed data servers, ferrite rings make communication channels almost noise-free to prevent interference; thereby improving the dependability of systems on a whole.

Ferrite magnets ring often make the right choice in selecting a magnet when it comes to specific application and we are going to see why they stand alone. Foremost among these is their relative cheapness; ferrites are much less costly than rare earth magnets such as neodymium, making them the perfect choice for consumer electronics in which every penny counts. In addition, their corrosion resistance and heat-resistance helps them to have a durable life even when the operating condition is tough. In addition, their non-toxicity makes them easier to work with and dispose of than some other magnetic materials.

Ferrite ring magnets are an appealing choice in the manufacturing world and to sustainability as a whole; hence why, these ferrites do present themselves very well for recycling. Made up mostly of a material originating in the Earth crust called iron oxide, these magnets can easily be recycled once they reach their end-of-life reducing environmental burden and conserving natural resources. Ferrites production, unlike some rare-earth magnets whose extraction can be environmentally hazardous, has fewer ecological risks. Power Strontium Ferrite & How it can power Recycling Initiatives Reusing ferrite and incorporating scrap Ferrlite into fresh products, hence reducing their carbon foot print but also significantly lower the need for extraction of virgin raw materials; all in-line with global efforts to implement circular economy principles.

Xinyuan is a high-tech company is a specialists in the manufacturing and sales of research and ferrite ring magnet. The company has introduced advanced jet mills that have high uniformity and rotary vacuums melting furnaces as well as low oxygen system productions lines for powers from all over the world. By using hydrogen alloys technology, the company has designed and manufactured magnetic components that are able to adapts to a variety of extreme conditions, and meet the requirements of every customer.

The company has created SGS and MSDS standards for quality inspections and established ISO9001 as managements system. In additions, it has ferrite ring magnet. Each production steps is monitored by skilled technicians. Additionally, we have a thorough quality control systems which performs completes quality checks before leaving the factory. The company meets its legal obligations and socials responsibilities to customers.

We have a rubbers pads between the magnets and vacuums sealed bags. There foams is placed in the middle of every cases to ensures that ferrite ring magnet. We can meets your needs for designs. Standards packaging for vessels and air or according to the customer's requirements.

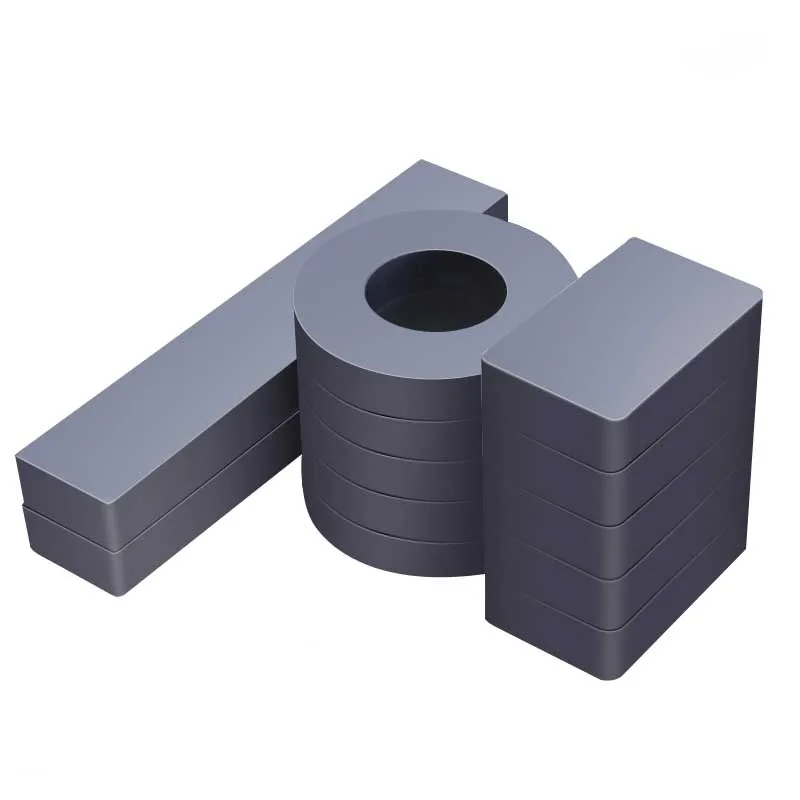

The main activity of the company is manufactures of universal magnet components and customs components. We offers a ranges of magnetic materials like the ferrite ring magnet, ferrite, and ferrite magnets.